- +61-416631973

- alcomgrouppty@gmail.com

- NSW , Australia

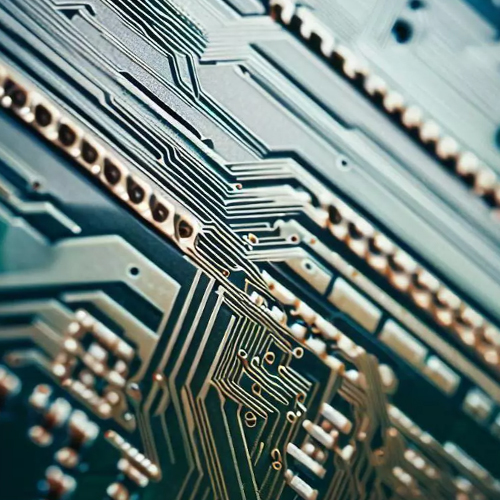

Double sided PCBs are a popular choice in the industry when it comes to printed circuit boards, as they allow for more complex designs, circuits and thus benefits for products.

Unlike single sided PCBs, double sided PCBs can mount the conductive copper and components on both sides of the board, as opposed to just the one. These double sided boards allow for closer routing traces as they can alternate between the top and bottom layers using vias. This can be very useful in many electronic products as the circuits on one side of the board can be connected to the other with the help of holes drilled onto the boardz.

Due to how they’re manufactured, double sided PCBs are a great choice thanks to their ease of use and flexibility. They also offer increased circuit density as the second layer means there is more capacity for PCB components than on single sided PCBs.

With this increased space, double sided PCBs use a more complex circuitry, meaning they are great for more advanced electronic systems such as lighting and car dashboards. These benefits can also come with a reduction in production cost because double sided boards are often smaller in size than other PCBs.

Alcom Group company vision to reach in every sector of industries which wants to give best service with value of price. The dream of the company who join the hands everyone has to develop with their skills and ability to make success.

©2019. Alcom Group. All Rights Reserved.

WhatsApp us