- +61-416631973

- alcomgrouppty@gmail.com

- NSW , Australia

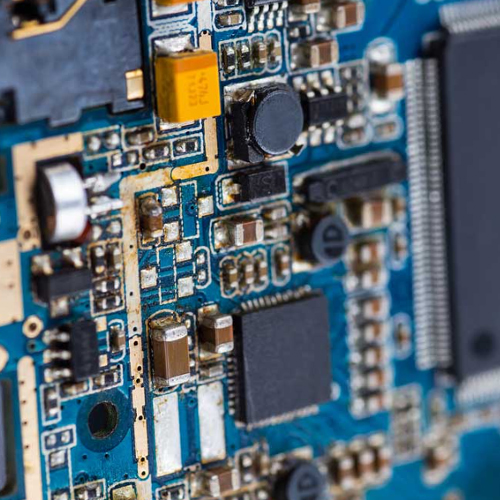

2 Layer PCBs are the most common type of PCB. Plus, 2 layer PCBs are also known as double-sided PCBs because they have components on both sides of the board.

The 2-layer pcb fabrication is by bonding two layers of copper together with a dielectric material in between. And the dielectric material can be either an FR-42 or an FR-44.

Furthermore, the copper on each side can carry different electrical signals, which makes them ideal for applications where high speed and/or dense packaging is necessary. 2 Layer PCBs are also the most economical type of PCB to manufacture.

Using a PCB ground plane provides advantages in terms of signal integrity, power integrity, routing, and noise:

Alcom Group company vision to reach in every sector of industries which wants to give best service with value of price. The dream of the company who join the hands everyone has to develop with their skills and ability to make success.

©2019. Alcom Group. All Rights Reserved.

WhatsApp us