- +61-416631973

- alcomgrouppty@gmail.com

- NSW , Australia

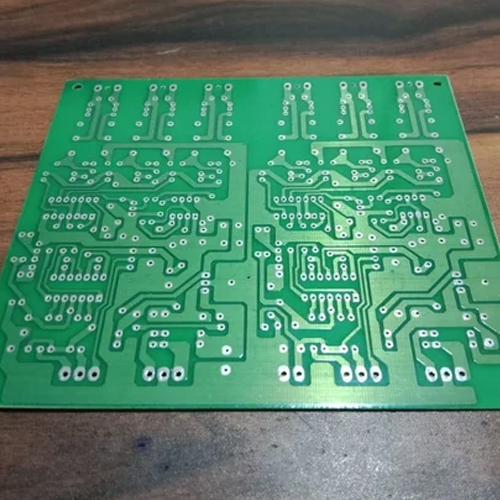

As these circuit boards are straightforward to produce and ideal for simple, low-density designs, this means they are one of the most commonly produced boards. Whilst their design and manufacturing may be simple they can still be used in many complex electronic devices, such as radio and stereo equipment, printers and even vending machines.

Because they can be produced in high quantities, with relatively low production costs, single sided PCBs are the board of choice for many. However, it is important to consider the needs of your project and whether a single sided PCB provides the capabilities and functionalities needed.

Alcom Group company vision to reach in every sector of industries which wants to give best service with value of price. The dream of the company who join the hands everyone has to develop with their skills and ability to make success.

©2019. Alcom Group. All Rights Reserved.

WhatsApp us